Portable Surface Quality Control and Hardness Measurements

Description of the Technology

The service offers surface quality control and hardness measurements for different kind of materials directly at client’s factory. Following measurements are offered:

a) The hardness measurement with PROCEQ Equostat 3 portable hardness tester (see. Fig. 1). The unit operates on a portable Rockwell (Portable Rockwell) methods which major pluses is minimal residual indentation depth of the material (~ 20 µm), the possibility to do measurements on curved shapes and thin (1mm) components, the possibility of doing measurements without disarranging device, as well as the possibility to carry out measurements on vertical surfaces. The kit is equipped with additional measuring clamp that provides faster and more precise measurement for cylindrical parts. The machine complies with standards DIN 50157, ISO 18625, ASTM B724.

Fig.1. PROCEQ Equostat 3 portable hardness tester.

More detailed information about device can be seen at webpage:

http://www.proceq.com/nondestructivetestequipment/metal-testing/obsolete-products/equostat-3.html

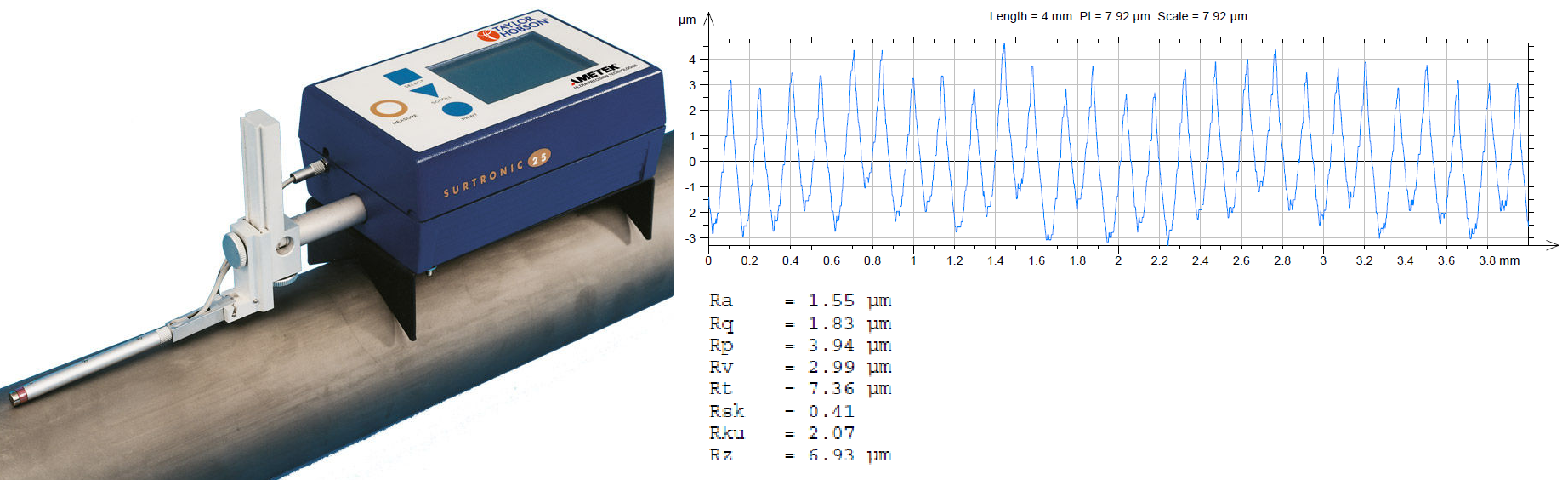

b) Surface roughness measurements with TAYLOR HOBSON Surtronic 25 profilometer (see. Fig. 2). Contact-type profilometer allows to make roughness parameter measurements for various form parts (shafts, bushings, flat surface, etc.). Besides the roughness parameters the system provides the ability to obtain the surface profile image, waviness image, roughness image, material distribution curve, make wear measurements. The machine complies with standard ISO 4287.

Fig.2. TAYLOR HOBSON Surtronic 25 profilometer.

More detailed information about device can be seen at webpage:

http://www.spectrum-metrology.co.uk/surface-roughness/surtronic-25.php

c) The surface texture and crack investigation with HIROX KH-7700 optical microscope (see. Fig.3.). Unlike traditional optical microscopes this one allows to take pictures for large and non-horizontal parts. It is possible because microscope lens can be moved by hands thus allowing to put it exactly where it is necessary for example to large-sized drive shafts. Lenses magnification can be changed in interval 50-400x. Microscope is also capable of forming a surface 3D images, as well as process filming at mentioned magnifications.

Fig.3. HIROX KH-7700 portable optical microscope with MXG-5040RZ lens.

More detailed information about device can be seen at webpage:

http://www.hirox-usa.com/products/microscope/index7700.html

d) Surface temperature measurement with DOSTMANN Proscan 520 temperature measurement system (see. Fig. 4). The device allows to measure temperature with both – contact and non-contact methods. The infrared method and different kind of thermocouples (for surfaces, gases and liquids) are used.

Fig.4. DOSTMANN Proscan 520 temperature measurement system.

More detailed information about device can be seen at webpage:

http://www.dostmann-electronic.de/product/id/271

Applications

• Different part (shafts, bushings, pins, plates, etc.) surface quality control directly at metalworking companies; • Hardness measurements for simple and complex shaped parts, including thin-walled parts (1mm); • Hardness measurements without disarranging device; • Hardness measurements for vertical surfaces; • Crack and fracture assessment; • Surface and other small product (for example microchip) 3D image acquisition; • Process filming at high magnifications; • Temperature Control for fixed and movable parts.

Advantages

- The biggest advantage of the service is opportunity to take measurements directly at your chosen location, i.e. the all equipment is fully mobile;

- Possibility to carry out a hardness measurement for large, complexed shaped, thin walled and vertically located components;

- Possibility to carry out a hardness measurement without disarranging device;

- The ability to do roughness measurements and get profile image;

- Possibility to carry out an examination with an optical microscope for large-sized parts;

- The possibility of filming processes at high magnification;

- Possibility to create small object 3D image;

- The ability to control the temperature for both stationary and moving objects.

Keywords

Portable hardness tester,portable profilometer,portable optical microscope,mobile diagnostic